Undergraduate students can contact the listed faculty members, and copy Michael Barry (mbarry1@iit.edu) and Karen Caruso (caruso@iit.edu), to obtain a recommendation for working on a research project. Students accepted for a RES-MATCH project will receive a $500 stipend upon completion of their semester research work. If approved for continuing an applicable project into the summer, students will earn an additional $500 upon completion of their summer research objectives.

Additive Manufacturing of Titanium Biomaterials

Professor: Amir Mostafaei (mostafaei@iit.edu)

Department: Mechanical, Materials, and Aerospace Engineering

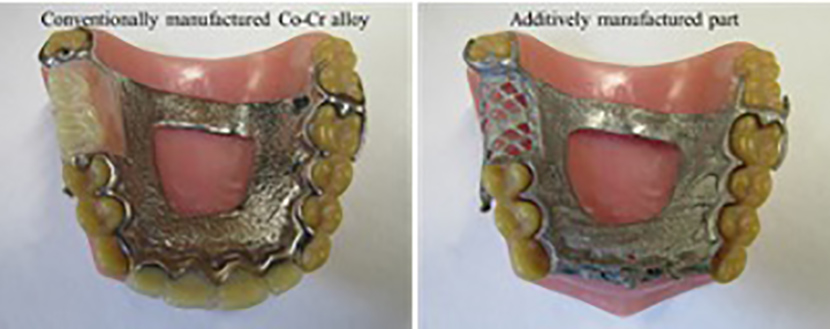

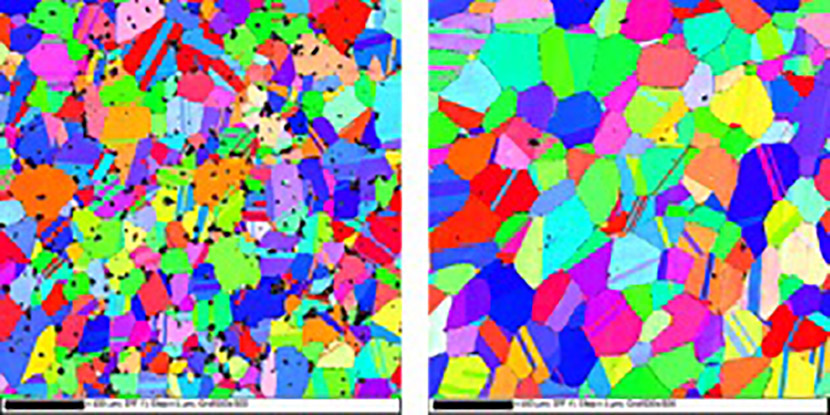

Brief description: Over the past decades, 3D printing or additive manufacturing (AM) has evolved substantially and has proven significant potential in biomedical applications, such as implants, prostheses, functionally graded structures, and hips/joints. 3D printing is a material-oriented manufacturing technology, since the solidification mechanism, architecture resolution, post-treatment process, and functional application are based on the materials to be manufactured. The proposed project aims to use non-spherical titanium powder in laser powder bed fusion additive manufacturing machine. 3D printed parts will be post processed including stress relieved and hot isostatistically pressed to understand effect of microstructure on hardness. Then, optimum process parameters will be used to manufacture a few examples related to biomedical engineering such as partial denture frameworks, dental crowns, and hips/joints. This research merges disciplines including materials science, advanced materials processing, and biomedical engineering. By both the manufacturing efficiency and the cost-effectiveness of the AM biomedical components made using high-quality, cost-effective powder, the knowledge gained from these investigations will provide significant opportunities for the biomedical industry.

Preferred student disciplines: Materials Science and Engineering, Biomedical Engineering

Preferred student skills: Motivated, enjoy manufacturing and characterization, know basics of materials science.

Expected student outcomes: This research aims to test the hypothesis that using a new double smoothing roller in powder bed fusion AM process can enhance powder packing density of non-spherical metal powder and result in high-density part production. Student work will include operating a laser powder bed fusion machine, feedstock and 3D printed part characterizations, and data analysis. The student can expect to work 8 hours/week.

Summer extension opportunity: This project can be extended into the summer, if spring objectives are met. The first objective for the spring is to develop an optimum process parameter and characterize test coupons for microstructure and defects. Summer work will focus on manufacturing of bioimplants and testing mechanical properties.

Fatigue Performance of 3D Printed Stainless Steel 316L Biomaterial

Professor: Amir Mostafaei (mostafaei@iit.edu)

Department: Mechanical, Materials, and Aerospace Engineering

Brief description: In recent decades, substantial progress has been made in the understanding, development, and utilization of additive manufacturing (AM) processes. Binder jet 3D printing, a non-beam based AM method, refers to the technology in which powdered material is deposited layer-by-layer and selectively joined in each layer with a thermosetting binder, then followed by post-processing to consolidate parts. Binder jetting can be used in biomedical and pharmaceutical industries. In the proposed work, we aim to advance the state of technology on binder jetting of ultra-fine powder (stainless steel 316L) incorporated with an innovative manufacturing system of using ultrasonic powder dispenser to enhance powder packing density and minimize powder bed defects. Sintering is a crucial step to densify as-fabricated parts to increase green density of 50% to > 99%. Sintering temperature will affect grain/pore evolution and resultant mechanical properties. We aim to correlate sintering temperature, microstructure and resultant mechanical properties via microstructure observations and tensile test. If successful, we will employ the gained manufacturing knowledge and apply it to topologically optimized implants to fabricate custom-made 3D printed parts.

Preferred student disciplines: Materials Science and Engineering, Biomedical Engineering

Preferred student skills: Motivated, enjoy manufacturing and characterization, know basics of materials science.

Expected student outcomes: This research aims to test the hypothesis that using ultrafine powder and an ultrasonic powder dispenser can enhance surface finish and fatigue performance of the 3D printed metal powder. Student work will include operating 3D printers, sintering, materials characterizations, and mechanical testing. The student can expect to work 8 hours/week.

Summer extension opportunity: This project can be extended into the summer, if spring objectives are met. The first objective for the spring will be process optimization for manufacturing of 3D printed 316L followed by sintering. Parts will be characterized for microstructure and defects. For the summer, we will focus on manufacturing of bioimplants and test mechanical properties.

In-Network Acceleration for Light Propagation Modeling

Professor: Nik Sultana (nsultana1@iit.edu)

Department: Computer Science

Brief description: Surgery is often the first line of treatment for patients diagnosed with solid cancer, where complete removal of the tumor(s) is not always achieved owing to challenges in detecting remaining cancer cells. It is estimated that up to 50% of patients with head and neck cancer receive incomplete surgeries because of particularly complex anatomy. To tackle this problem, our collaborators at the University Medical Center Groningen in the Netherlands have initiated the first clinical trial using cancer-targeted fluorescence agents injected into patients prior to surgery to help better identify remaining cancer in their patients so that it can be removed. To assist with these efforts, we have been developing advanced imaging strategies to help detect even the smallest amounts of cancer. Optimization of these strategies requires accurate understanding of how fluorescent light propagates through biological tissue at the margins of cancer resections. However, accurate simulations are restrictively time consuming using current methods. The goal of this project is to use cutting-edge computational methods to significantly amplify the efficiency of light propagation modeling.

Preferred student disciplines: Computer Science and other STEM fields

Preferred student skills: Good programming and debugging skills in Python, proficient in C or C++, good grasp of computer networking

Expected student outcomes: This research will model a computer cluster that contains modern networking hardware that can execute simple programs on traffic as it crosses the network. We’ll use this capability to model the propagation of light through tissue. the student will strengthen their technical skills and pick up new ones such as learning how to program in the language used for in-network programs.

A Device for Mosquitos Entrapment for Genetic Testing

Professor: Ali Khounsary (akhounsa@iit.edu)

Department: Physics

Brief description: Malaria a deadly illness killing about half a million people each year in poor countries. Infection occurs when a person is bitten by particular infected female mosquitos. The threat posed by an individual mosquito depends on its species, gender and age, and this information is critical in determining where, when and how to intervene to eradicate them. Different mosquitos have different habits and habitants. It has been shown that the required information can be obtained through a simple genetic test. This aids in identification and the appropriate targeting of mosquitos.

Recently, a relatively inexpensive and compact device has been developed and used for rapid genetic testing of mosquitos. A mosquito is captured, crushed, and then tested using this device to identify it. This requires significant labor and limits the use of this device. Remote and automatic operation of such a device is desirable as it offers immense advantages. It can test and relay the results remotely enabling a large number of these devices be employed covering a large area continuously and with ease.

The idea behind this res-match project is to continue the work initiated last semester to develop an adjunct electro-mechanical device that attracts, traps, and delivers mosquitos to the testing device for genetic analysis on a continuous basis so that the entire operation is automatic, economical, continuous, and remote.

Preferred student disciplines: No preferred disciplines

Preferred student skills: Background in mechanical engineering, electronics, coding, and 3D printing are helpful. Interest in research is required.

Expected student outcomes: The student's tasks include a general review of the subject, an examination of our early-stage prototype in the lab, and ideation & planning for the next phase in the development of a working prototype, which involves design, fabrication, and assembly of parts into a prototype. Depending on the progress and student’s interest, image processing provisions can be added. The student can expect to work 10 hours/week.

Auto-dispensing Prophy

Professor: Ali Khounsary (akhounsa@iit.edu)

Department: Physics

Brief description: Dental prophylaxis is a dental procedure which is performed at regular intervals to reduce risk of gum and tooth disease. The “cleaning” procedure uses many hand-held or ultrasonic instruments. One of the devices that is routinely used is the ‘prophy’ which is used to polish teeth after the cleaning.

A prophy is an all-plastic part with a small cup at one end as shown. It is attached to a hand-help device to provide rotation of the shaft and thus the cup through a gear system. Prophy paste consisting of abrasives is removed from small containers and manually placed onto the cup. The abrasive is worked onto the teeth by the rotating cup, cleaning and polishing teeth. As the abrasive is used, the dentist will load the cup again and again some 10 times during each session.

The purpose of this project is to eliminate the manual placement of the paste onto the cup by loading the paste onto the prophy for automatic delivery. This process will be faster, more hygienic, and reduces paste usage. During the past semester, significant progress was made on this project which can be built upon during this semester.

Preferred student disciplines: No preferred disciplines

Preferred student skills: Required skills include a strong background in mechanical design and CAD. Familiarity with 3D printing and fluid mechanics is helpful.

Expected student outcomes: The project involves reviewing some background information, examining several design ideas, selection and implementation of one of the designs, design and fabrication of parts, and assembly and testing of a prototype. The student can expect to work 10 hours/week.

Development of a PharynxScope for Telemedicine

Professor: Ali Khounsary (akhounsa@iit.edu)

Department:Physics

Brief description: Telemedicine is the practice of medicine remotely. This often requires devices at the patients’ disposal that the healthcare provider can use for remote diagnoses and monitoring. It makes healthcare more accessible and cost-effective. Telemedicine will be an increasingly important part of the healthcare infrastructure requiring a wide variety of medical devices that are remotely operable.

Examination of the larynx, throat, and mouth is currently done in person at the physician's office. We would like to develop a telemedical device, a PharynxScope, to do so remotely.

In this device, a common tongue depressor would be equipped with an electro-optical attachment that takes and transfers images to a remote healthcare professional in real time. The device is self-administered. Patients can simply place the tongue depressor with its attachment in the mouth as instructed so the healthcare professional can clearly see the condition of the patient's mouth and throat.

The purpose of this project is to develop a lightweight, inexpensive, potentially disposable electro-optical device composed of a microprocessor, communication provisions, a light source, a camera, and the necessary optics packaged in a compact configuration that slides over and clips to any common tongue depressor.

Preferred student disciplines: No preferred disciplines

Preferred student skills: A solid background in engineering (electrical, bio, mechanical, etc.) and familiarity with electronics and coding are required.

Expected student outcomes: The student's tasks include a review of the topic including patents and products, electronic and mechanical design of the device, parts selection, purchase, assembly and packaging, coding and testing the device. The student can expect to work 10 hours/week.